Top 5 Maintenance Tips to Extend the Life of Your Diesel Engine

Top 5 Maintenance Tips to Extend the Life of Your Diesel Engine

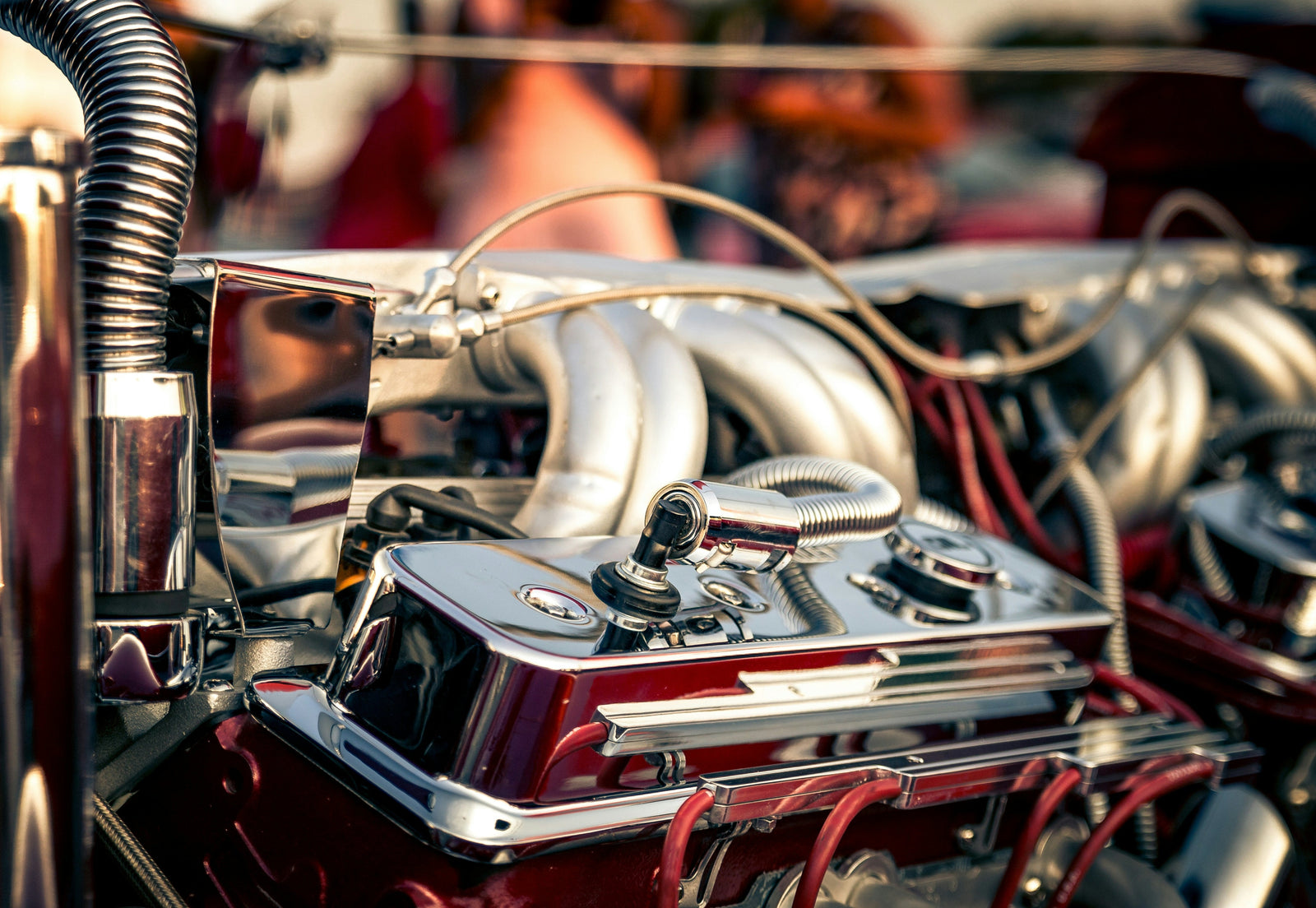

Diesel engines are known for their durability and efficiency. However, their longevity isn't just a matter of design. Proper maintenance plays a crucial role. It can extend the life of your diesel engine and improve its performance.

This article will provide you with the top five diesel engine maintenance tips. These tips are practical and easy to implement. Whether you're a diesel engine owner, operator, or mechanic, these tips will be beneficial. They will help you prevent costly repairs and unnecessary downtime.

We'll also discuss the importance of following the manufacturer's maintenance schedule. This is key to ensuring the reliability of your diesel engine. So, let's dive in and explore these maintenance best practices. Your diesel engine will thank you for it.

Understanding Diesel Engine Maintenance

Diesel engines are complex machines that require regular attention. Maintenance ensures they operate efficiently and last longer. The key is to identify potential issues before they escalate into major problems.

Routine maintenance includes checking oil levels, inspecting air filters, and ensuring the fuel system is clean. These checks prevent issues such as poor fuel efficiency or engine wear. To further streamline your maintenance efforts, consider using Tripak’s 5 in 1 Diesel Conditioner. This advanced additive enhances fuel quality, reduces engine deposits, and optimizes performance.

Implementing these tips can significantly boost engine performance. A well-maintained engine not only runs smoother but also pollutes less. This is a win for both your vehicle and the environment.

Tip 1: Oil and Filter Management

Effective oil and filter management is crucial for engine health. Diesel engines rely heavily on proper lubrication to function smoothly. Dirty oil or clogged filters can lead to significant wear and tear. Tripak’s Anti-Friction Metal Treatment (AFMT) can complement your oil system by reducing friction and wear, even under extreme conditions.

Here are some oil and filter management best practices:

- Use high-quality oil and filters suitable for your engine.

- Follow the recommended change intervals to avoid oil degradation.

- Check oil levels frequently to ensure engine parts are well-lubricated.

Tip 2: Fuel System Care

A well-maintained fuel system ensures clean fuel flows to the engine. Diesel engines are particularly sensitive to fuel quality. Regular use of Tripak’s Diesel Conditioner not only improves fuel quality but also protects against corrosion and algae buildup.

Keep in mind these best practices for fuel system care:

- Regularly inspect fuel lines and components for leaks or wear.

- Use diesel additives to enhance fuel quality and prevent issues.

- Replace fuel filters at regular intervals.

Tip 3: Air Intake and Cooling System Maintenance

Maintaining clean air filters and a functional cooling system is critical for diesel engine performance. Additionally, using Tripak LDL-1 can help keep engine components in excellent condition. This versatile product is ideal for protecting critical areas, as it effectively removes corrosion, drives moisture away, and provides insulation from electrical leakage.

Here are some best practices:

- Inspect and replace air filters regularly to ensure proper airflow.

- Check coolant levels and flush the system as recommended to avoid overheating.

- Apply LDL-1 on metallic components to prevent rust and extend their lifespan.

By integrating LDL-1 into your maintenance routine, you can enhance the durability of air intake and cooling system parts while ensuring optimal performance.

Tip 4: Battery and Electrical System Upkeep

Diesel engines rely heavily on the proper functioning of their battery and electrical systems. Regular inspections, combined with the use of Tripak LDL-1, can protect these vital components. This product is especially effective at removing corrosion from battery terminals, driving away moisture from electrical components, and insulating them to prevent electrical leakage.

Key maintenance practices include:

- Check battery charge levels frequently and clean the terminals with LDL-1 to prevent buildup.

- Apply LDL-1 to electrical connectors and wiring to ensure proper insulation and reduce the risk of shorts or damage from moisture.

- Replace batteries as needed to avoid unexpected breakdowns, especially in extreme weather conditions.

By using LDL-1, you’re not only extending the life of your battery and electrical components but also ensuring your diesel engine starts reliably every time.

Tip 5: Regular Inspections and Professional Diagnostics

While regular self-inspections are important, professional diagnostics ensure no detail is overlooked. Consider scheduling regular maintenance services with professionals who understand how products like Tripak's additives can enhance your engine's performance.

Conclusion: The Long-Term Benefits of Tripak and Diesel Engine Maintenance

Incorporating Tripak products into your diesel engine maintenance routine ensures optimal performance and longevity. These advanced solutions reduce wear, improve efficiency, and help prevent costly repairs. Commit to these practices and see the difference in your engine’s reliability and performance.